Anjing Road, Xiaolan, Zhongshan, Guangdong, China

info@mes-drive.com

08.00 AM-09.00 PM

Introduction

On 14 October 2024, the European Parliament adopted a landmark plan to double the continent’s public electric‑vehicle (EV) charging points by 2030. The initiative, part of the EU’s Green Deal and backed by Germany’s ambitious “Invest In Green” budget, has already sparked a wave of headlines across tech blogs, finance news, and social‑media feeds. For industry watchers, the new policy signals a rush of infrastructure investment and a surge in demand for cutting‑edge components that power EV charging stations, battery modules, and the vehicles themselves. Among these components, gear motors (or reducer motors) play a pivotal role—yet they remain a quiet hero behind the gleam of electric motors on roads.

Why Gear Motors Matter in the EV Ecosystem

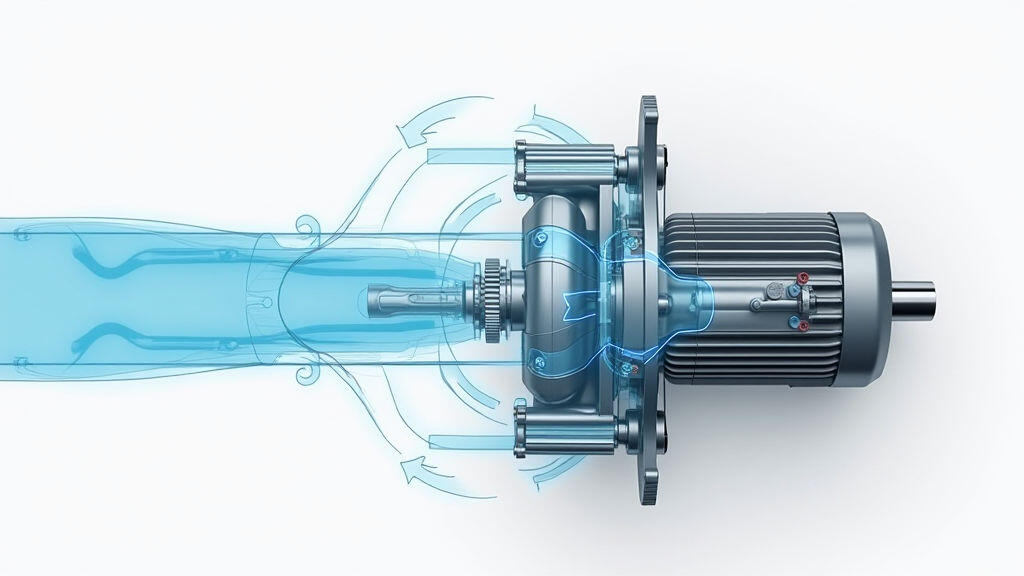

A gear motor couples an electric motor with a gearbox, delivering high torque at low speed while maintaining compact size and efficiency. This combination makes them ideal for several key applications in the EV ecosystem:

Charging Station Control Systems

Modern fast chargers contain a power‑conversion chain that must precisely regulate voltage, current, and temperature. Gear motors are now often used to drive the cooling fans, hydraulic pistons, and even the safety handles that secure the charger’s high‑voltage cables. Their compactness, reliability, and low maintenance help operators keep stations up and running with minimal downtime.

Battery Management Systems (BMS)

The BMS monitors cell temperature and balance. Many European designs incorporate small gear motors to actuate the variable‑capacity cooling plates that keep battery packs within an optimal temperature envelope. The ability to deliver consistent torque over a broad speed range means precise temperature control, which directly translates into longer battery life and greater safety.

Vehicle Inverter and Transmission

Although the core traction motor in most EVs is a high‑speed, low‑torque unit, gear motors are often found in the inverter’s drive assembly. They convert the high‑frequency, low‑torque AC output into the mechanical torque needed to turn the gear ratios that drive the wheels. European car manufacturers, especially German giants, are shifting to high‑efficiency gear motors in new EV models to meet stringent fuel‑efficiency and emissions targets.

Technology Meets Demand: The Market Ripple

The EU’s policy decisions have catalyzed a multi‑layered demand surge for gear motors:

A recent report by the European Industrial Outlook noted that gear motors are projected to grow at a CAGR of 12% from 2024 to 2030, with the charging station segment leading the market. This estimate aligns with the EU’s own infrastructure investment plans, which allocate 7.5 billion euros to accelerate charging networks.

Case Study: German EV Charger Prototype

A German startup, VoltTech Industries, recently unveiled a prototype level‑3 charging station that boasts a 200‑kW output using an innovative gear motor‑driven cooling system. The motor’s integration eliminates the need for bulky cold‑air compressors, reducing weight by 30% and cutting operating costs by 18%. The startup’s spokesperson highlighted that “the gear motor’s reliability and low maintenance mean fewer service calls, making the charging station more attractive to municipalities.”

Innovation Outlook: Flexible Gear Motors for Rapid Integration

Smart grids and the sharing‑economy model demand EV chargers that can adapt to fluctuating loads and network constraints. Gear motors that combine variable torque output with sensor‑based feedback allow charging stations to operate efficiently under diverse operating conditions. By leveraging Industry 4.0 technologies, manufacturers are embedding microcontrollers that oversee motor speed and temperature in real time, enabling predictive maintenance and energy‑efficient operation.

Additionally, as EU regulations encourage the use of renewable energy sources for charging, gear motors must be compatible with fluctuating input voltages derived from solar panels or wind turbines. High‑efficiency, torque‑balanced gear motors can smooth power delivery, preventing damage to both the charger and the vehicle battery.

Conclusion

The EU’s ambitious push for a pan‑European EV charging grid represents a monumental step toward a carbon‑neutral transport sector. While the headlines focus on charging points and battery technology, the foundation of this infrastructure is built on component reliability and precision—especially gear motors. These reducers provide the unseen torque, stability, and safety features that make charging stations viable, battery systems efficient, and EVs practical for everyday use.

In the next decade, as the EU’s green energy targets tighten, the demand for advanced gear motors will only intensify. Manufacturers who innovate in material science, digital integration, and sustainable production will reap the rewards of a rapidly expanding market. Thus, gear motors are not just mechanical accessories; they are essential catalysts accelerating Europe’s transition to electric mobility.

Future-oriented investors, tech developers, and policy makers alike should recognize the strategic importance of this humble device—because every step toward a greener future is turned forward by the precise, reliable torque that a gear motor delivers.

Leave A Reply

Your email address will not be published. Required fiels are marked